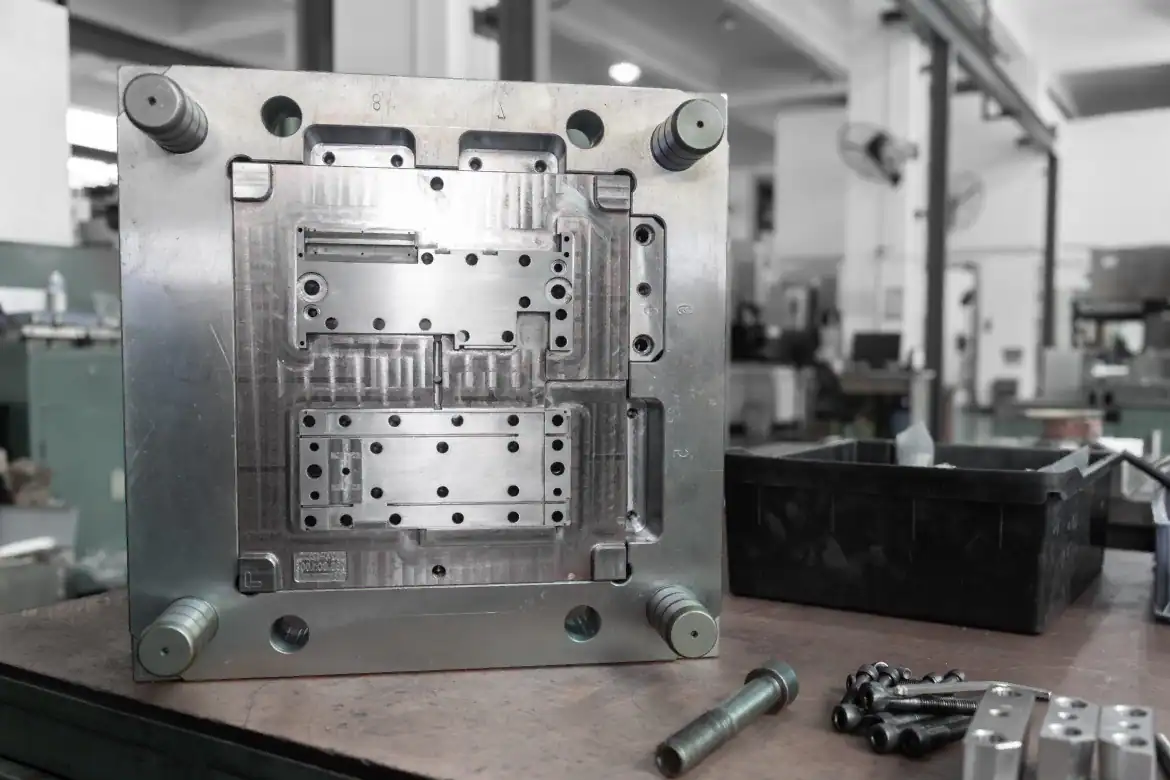

Precision Quality Control for Thermoplastic Molding

At Polymar, we know that product quality directly impacts our customers' success. Our commitment to excellence shows in our modern Quality Assurance Laboratory and thorough quality control processes. We aim to surpass industry standards and fulfill the specific requirements of our diverse client base.

Advanced Quality Assurance Laboratory

Our Quality Assurance Laboratory features top-tier mechanical and optical inspection equipment, confirming that every component we produce meets strict quality and precision standards. Many inspection tools connect with computing instrumentation, generating various chart print-outs for statistical analysis during production.

This sophisticated setup allows us to:

- Analyze materials upon receipt and during production

- Monitor processes for maximum polymer integrity

- Conduct real-time quality checks

- Provide detailed quality reports to customers

Comprehensive Quality Records

We keep detailed records and specifications in our quality laboratory. These are available for review by:

- Our customers

- Underwriters Laboratory

- ISO Auditors

This transparency highlights our quality commitment and builds strong customer relationships.

Your In-House Quality Representative

At Polymar, our quality assurance staff functions as our customers' in-house representatives. They work diligently to confirm every product meets or exceeds customer expectations, offering an additional layer of confidence in our output quality.

Advanced Quality Control Measures

To maintain the highest standards, Polymar implements several key quality systems:

Metrology

Our QA Manager and staff hold ASQ Certification in Metrology, supporting all measurement and calibration aspects to maintain accuracy and precision in our production processes.

Statistical Process Control (SPC)

We use the MATTEC real-time manufacturing execution system software to provide customers with:

- Capability Process Index (CPK) Data

- X-Bar & R Charts

- Histograms

This statistical approach helps maintain consistent quality across production runs and quickly identify any deviations.

"Smartscope" Video Inspection

We use a "Smartscope" video inspection machine from Optical Gauging Products. This technology delivers highly accurate and repeatable measurements, confirming our products meet strict dimensional requirements.

PPAP, FAI, Process Capability and Scientific Molding

Based on industry and specific customer needs, we conduct:

- Production Part Approval Process (PPAP)

- First Article Inspection (FAI)

- Process Capability Studies

- Scientific Molding studies

These tools prove our ability to consistently produce parts meeting rigorous standards.

Industry Certifications

Our quality commitment gains further validation through our industry certifications:

UL Recognized Component Molder (RCM)

We are a UL Recognized Component Molder (RCM) with registration number A1437. This certification shows our ability to produce components meeting UL's strict safety and quality standards.

ISO 9001:2015 Registered

Polymar maintains ISO 9001:2015 registration, confirming our dedication to a quality management system meeting international standards. This certification verifies we consistently provide products and services fulfilling customer and regulatory requirements.

Our Quality Philosophy

At Polymar, quality extends beyond a department—it's a philosophy present throughout our operations. From material selection to final inspection, we maintain thorough quality control processes to confirm every component meets excellence standards.

Our Quality Assurance Laboratory, experienced quality staff, and industry certifications give customers confidence their products will perform as expected, every time. We continuously invest in quality assurance capabilities to remain at the forefront of industry standards and exceed customer expectations.

Choose Polymar for your thermoplastic molding needs and experience the confidence that comes with a partner dedicated to unwavering quality.

Polymar delivers precision-molded thermoplastic components with rigorous quality controls and industry certifications. Contact us to learn how our quality systems can support your manufacturing needs.