Services

Nothing at Polymar just happens. It has all been planned, recorded, checked and rechecked.

Polymar’s Injection molding services in Leola, PA experience include miniature electronic components weighing fractions of an ounce to large industrial parts of five pounds or more.

OUR Experience

Polymar’s Injection molding experience includes miniature electronic components weighing fractions of an ounce to large industrial parts of five pounds or more. Our material experience ranges from the simplest commodity resins through the reinforced, lubricated, flame retardant grades to the exotics, PVC, CPVC, and fluorpolymers.

Polymar’s tooling programs guide our customers to the most efficient, technical and cost effective production goals. Intricate product design, tool design and polymer specifications are all within our repertoire. Given the opportunity to quote and review your sketch or product drawing, we will respond with an estimate of material weight, cycle time, and a helpful recommendation for economics and function.

How we Work with Our Valued Partners

Polymar provides timely, fast delivery with fair, competitive pricing. We work with you to produce your proprietary part designs. Our engineers are ready to support you on new products, and our team works hard to take good care of our valued customers. At Polymar, we are focused on a one-stop shopping experience for all your injection molded and related project needs.

You are a valued partner. What sets us apart isn’t the “what we do,” but “how we do it”: Polymar understands the importance of consistency in the value equation. Nothing at Polymar just happens. It has all been planned, recorded, checked and rechecked.

Value-added Services

In addition to servicing your injection molding needs, Polymar also performs sonic welding, hot stamping, and assembly on cycle services. When shipping, we are able to bar-code the carton labels with information specified by the customer and arrange any needed customized supply chain arrangement. Polymar is also EDI capable on purchase orders, functional acknowledgements, and advance ship notices.

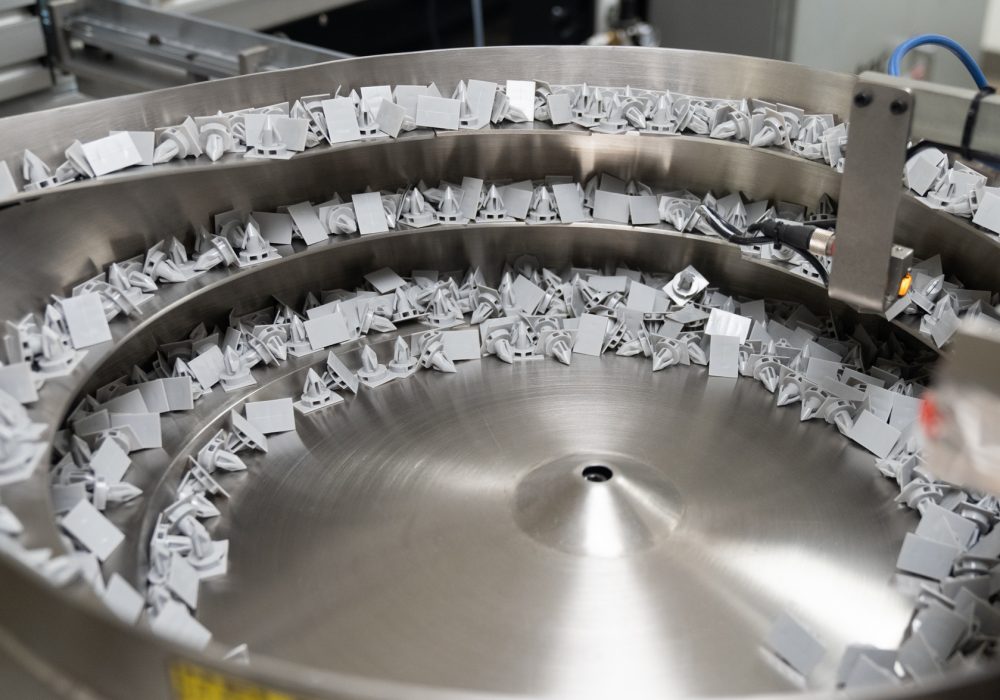

Dosimetry Badge Holders

Since 1983, Polymar has been producing badge holders for the TLD dosimetry industry in both civilian and military applications. Typically used in nuclear power plants or when working with radioactive material, these holders and the dosimeter measure the amount of radiation exposure in a given time period.

To maintain quality assurance, accumulated holders are inspected by the molding machine operator on cycle.